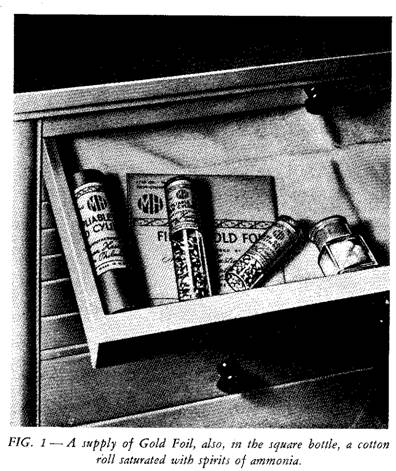

a cotton roll, saturated with

spirits of ammonia and, to avoid staining, kept in an open small bottle.

When the operator prepares forms of his own — pellets,

ropes, etc. — and the Foil is handled with the fingers, it is advisable always

to wear chamois finger-tips. This will provide complete protection from moisture

on the skin.

AIM and METHODS of ANNEALING

From the foregoing, it is plain that the annealing of Gold Foil presupposes its express protection, and that the general aim of annealing is to drive off its surface all atmospheric moisture and whatever film has been formed by the protective alkaline gas in combination with gases that may have settled afterward.

PROPER ANNEALING is then a matter of heating Gold Foil long enough, at a given temperature, to volatilize all moisture and gases, of cleansing all its surface, of avoiding injury to the Foil in the process, and of guarding it against all contamination, from the start of its annealing to its condensation in the cavity.

UNDERANNEALING is to be avoided. It leaves impurities on the

Foil, which prevent its thorough condensation. and thus cause the restoration, eventually, to pit and

flake. OVER-ANNEALING is to be avoided no less. It scorches the Foil, shriveling

the fine edges, and rendering it generally harsh and unworkable — with the same

harmful consequences as those of underannealing. It

can be the cause of some of the difficulty encountered, especially by

beginners, in seating the first third of a Gold Foil restoration. And scorched

Foil will not burnish properly. As to CONTAMINATION of Gold Foil during or

after annealing, it may be as harmful, obviously, as contamination before

annealing.

Gold Foil can be annealed, in general, by either of two

methods: (1) piece by piece, in an open flame; or (2) in bulk, on a tray or

some other suitable receptacle. Each has its advantages and disadvantages, and

either is capable of giving satisfactory results.

To ascertain current annealing practices, Morgan, Hastings

& Co. recently sent out a questionnaire to dentists in various parts of the

country. The answers received were divided between the two methods about

evenly: those from dentists who annealed piece by piece totaled 247, while

those from dentists who annealed in bulk totaled 234. Many an operator quite

naturally believed his favorite method to be superior; and there were in each

group about an equal number of those who reported having had satisfactory

results for as long as 20 years. On the other hand, there were in each group

also those who had tried the alternative method and found it less satisfactory.

Then again, there were some who, according to circumstances, now used one, then

the other, with equally good results.

And so it seems reasonable to conclude that either method is sufficiently satisfactory in itself and

that success depends entirely on its being employed with understanding and

care. The choice is thus a question simply of the operator's personal

predilection. He would evidently do well to adopt the one that is more to his

liking.

The two methods of annealing are described in what follows — which also further summarizes the findings of the aforementioned questionnaire.

ANNEALING PIECE by PIECE

The method of annealing piece by piece consists in picking

up each piece of Gold Foil, of whatever form, individually, heating it directly

in an open flame, and placing it in the cavity.

The instrument best adapted for carrying the Foil is one

with a fine, smooth point. Pliers, even with the smallest beaks, are less

practical. The part of the Foil that is covered by the beaks is annealed less

thoroughly than the part that is exposed to the flame fully, necessitating a

second annealing, for which the position of the grasp must be changed so as to

expose fully the part insufficiently annealed the first time. Not only does

this take longer; it increases the hazard that a portion of the Foil may be overannealed.

The instruments used for the purpose are ingeniously various.

Particularly excellent is one devised by Dr. Charles E. Woodbury. Its nichrome point is easily kept sharp and smooth; in contrast

to that of steel, which soon becomes carbonized and rough. It is better also

than one of gold or platinum, which tends to dull easily, and to stick to the

heated Foil. An instrument of Dr. Woodbury's specifications can be made by the

operator simply by sharpening and smoothening one end of a piece of 16-gauge nichrome wire, bending it like an explorer, and setting the

other end into a broach-holder.

A similar instrument in common use is made by flattening and sharpening an old stainless-steel explorer to a spear-like point. Or, with a Joe Dandy disk, the flattened explorer is made into a tiny fork. Some employ, set into a broach-holder, an old broach with its barbs clipped off, or a piece of iridio-platinum wire with one end sharpened. The latter is usually bent like an explorer. Other operators, mostly those working without an assistant, pick up the Foil on the point of the condenser.*

* The term

"condenser" is here adopted in place of "plugger"

at the instance of Dr. James Mark Prime, as well as in recognition of its

growing favor with members of Gold Foil study clubs generally. Its advocates

argue that it describes the real purpose of the instrument more accurately than

"plugger"; an opinion with which it is easy

to go along.

Whatever the instrument, its point should be nonoxidizing, and it should pick up the Foil so as neither

to crush it nor to cover any portion of it. And it should obviously be cleaned

just before use. Simply scrub it with a stiff nail-brush dipped in alcohol,

and then dry it thoroughly with a towel.

The fuel for the flame may be alcohol or gas (the latter may

be natural or manufactured). Alcohol is widely preferred; gas is believed to be

more intense, also more carbonizing. The alcohol, whether

from wood or from grain, should be chemically pure. Denatured alcohol

is seldom satisfactory; most denaturing agents yield an overplus

of carbon and are contaminating. An increasingly popular brand of alcohol is

that known as Methanol.

When the annealing is done with an alcohol lamp, the flame

should be moderately strong, of a clear light-blue color, and free from soot.

This requires not only that the alcohol be right, but that the lamp be

thoroughly clean, and that the wick not be up too high. In lighting the lamp,

the match is not to touch the wick, or else enough sulphur

may stick to it to contaminate the Foil during annealing. Apply the flame of the

match to the extreme edge of the wick. Or light a toothpick with the match, and

then light the lamp with the toothpick. In any case, the charred part of the

wick is to be trimmed off after each annealing. Some remove it by rubbing the

wick with a towel.

The Foil is passed through the flame at the tip of the inner cone — neither close to the wick nor through the upper portion of the outer cone. Either of the latter may contaminate it with carbon. It is passed through the flame - not held — at a rate that will bring every particle to a dull red. If kept in the flame till it shows a bright glow, it is liable to be overannealed before it can be withdrawn. Heating it to a dull red usually takes no longer than the count of two. The exact length of time depends on the size of the piece and on the intensity of the flame. Gauging it, is entirely a matter of feel, which comes with experience.

When annealing with a Bunsen gas burner, be sure to have a

reducing flame, and turn it down to about an inch high. Pass the Foil through

the middle of the flame, somewhat more quickly than through an alcohol flame.

Whatever the fuel, the hazard of open-flame heating is not

so much that of underannealing as that of overannealing. One must always guard against it. If a piece

comes out of the flame looking the least bit shriveled, it is doubtless

scorched, and is best discarded.

Every annealed piece, in all open-flame annealing, is

carried-from the flame direct to the cavity. This has the important advantage

of precluding all possible contamination of the Foil after annealing, whether

by atmospheric moisture or gases or by substances that can contaminate it on

contact. A common procedure is as follows. While malleting

an annealed piece with one hand, the assistant picks up a fresh piece with the

other. When the condensation of the former is finished, she then anneals the

latter and carries it to the cavity. And so on till the restoration is

completed. On reaching the cavity, the Foil should have cooled sufficiently not

to cause any painful reaction. Its cooling can be hastened by waving it in the

air for an instant.

Other operators have the assistant anneal a piece immediately

after placing one in the cavity. While the latter is being malleted,

the former, on the foil-carrier, is then cooling.

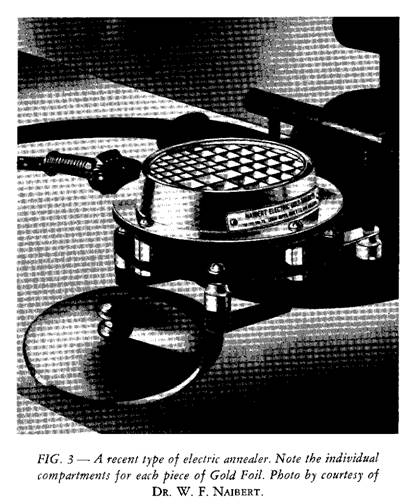

According to the most recent reports, the method of annealing piece by piece is increasingly giving way to that with an electric annealer, described below.

ANNEALING in BULK

Annealing in bulk is done by spreading a number of pieces of

Gold Foil, of whatever form, on a tray or some other suitable receptacle,

heating them through the latter, and placing them in the cavity one by one.

Of the various receptacles in common use, mica, as a sheet

or a disk, was formerly a standby. When used as a sheet, its size averages

about four inches square, and it is held over the flame, of an alcohol lamp or

a Bunsen burner, with ordinary cotton-pliers. About 10 pieces of Foil, spread

out so that no two pieces touch each other, are laid out in the central portion

of the sheet; the flame, which is to be of a clear light-blue color, is turned

on fairly strong; and the mica is then held over it, with-out quite touching

it, until it (the mica) turns a dull red. The actual annealing time is about

five or six seconds. The exact length of time varies, of course, with the

intensity of the heat and with the size of the different pieces. The annealed

Foil is removed to a clean, dry napkin or a clean piece of chamois skin, from

which it is carried to the cavity piece by piece.

The mica should be sound and clean. Mica that has begun to

check or flake is an unnecessary hazard. The condenser should be cleaned just

before picking up the first piece. As previously suggested, simply scrub it

with a stiff nail-brush dipped in alcohol, and then dry it thoroughly with a

towel.

More operators, of those answering the aforementioned

questionnaire, have reported difficulty with this mode of annealing than the

total number of the operators who have found difficulty with each of the other

procedures. The reasons are various. First of all, there is the hazard of simultaneous

over-annealing and underannealing. Because the degree

of heat reaching the different pieces is not uniform, those farthest from the

hottest point of the flame may remain insufficiently heated even though those

directly over it are already overheated. To minimize this troublesome

variation, some operators, instead of holding the mica in one position, pass

it, slowly, over the flame to and fro, distributing the heat more evenly

throughout the surface.

There is another disadvantage, after annealing. It is rather

difficult to remove the Foil to the napkin or the chamois skin without some of

the pieces sticking together.

Still another disadvantage, also after annealing, concerns

the possible contamination of the Foil while lying on the napkin or the chamois

skin, waiting to be placed in the cavity. Even when it is hot, it may be

contaminated by dust or acid gases; while as soon as it has cooled, it may be

contaminated also by moisture or volatile gases.

When the weather is humid, atmospheric moisture should be guarded against especially. And while the Foil is thus exposed, it is best not to light a match. Also, if there is any odor of smoke coming in from the outside, it is well to close the windows, shutting out the contaminative sulphides that abound in the smoke of coal or oil.

MICA ANNEALING TRAY: Mica is used also to form what is known

as a mica annealing tray. The latter consists of a metal stand designed to be

mounted on an alcohol lamp or a Bunsen burner and of a disk of mica that fits

as its top. The underside of the mica comes to within an inch or so of the

flame.

As many as 20 pieces of Gold Foil,

spread out so that no two pieces touch each other, may be placed on the tray at

a time. The flame is turned on a bit stronger than under a plain sheet of mica,

and the Foil is heated till the mica begins to show a tinge of red. The average

annealing time is about five minutes. The flame is then turned down a little

and left on till the Foil is used up. The annealed Foil is carried from the

tray direct to the cavity, with the pieces in the center of the tray picked up

first and the outer ones last. Additional batches are annealed in the same way,

with care being taken to limit the final batch to the estimated number of

pieces still required to complete the restoration.

The mica tray has obvious advantages over the sheet of mica

held with pliers. For one thing, it allows more pieces to be annealed at a

time. Secondly, its slower heating tends to reduce variations in the degree of

heat reaching the different pieces, thus reducing the hazard of simultaneous overannealing and underannealing.

Furthermore, carrying the annealed Foil from the tray direct

to the cavity — without first removing it, in a mass, elsewhere— excludes the

handling that could cause some pieces to stick together. And keeping the

Foil warm till it is used up, safeguards it against moisture and volatile

gases. Acid gases, however, are still a danger. So is of course also dust.

The care with respect to the cleanliness of the mica and the

condenser should obviously be exercised here too.

There are also other annealing devices for mounting on an

alcohol lamp or a Bunsen burner. Instead of a mica tray, they have a tray of

PORCELAIN, ENAMELED METAL, or SOAP-STONE. The procedure is the same as that

with the mica tray in all respects but one. Being less conductive of heat,

these trays

require, variously, both a stronger flame and longer heating. The annealing time ranges from 10 to 20 minutes, when the flame is turned down so as merely to keep the Foil warm.

ELECTRIC ANNEALER: Still another and the latest means of

annealing in bulk is that of an electrical device designed